Wax Emulsion

Wax Emulsion And Application

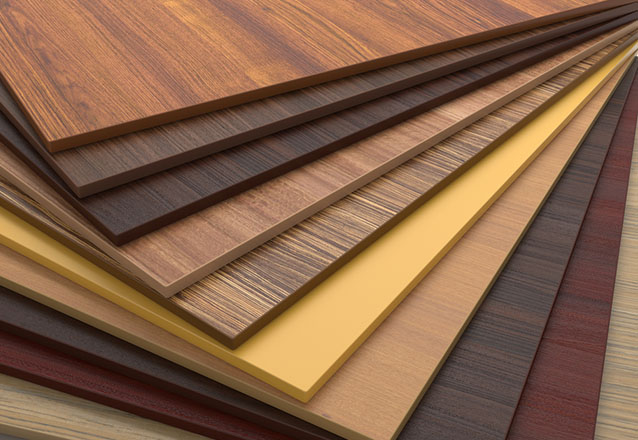

Wax emulsion is used in woodworking industry to protect wood boards (Particle board, MDF, OSB) from water. Wax emulsion has anti-dust effect which is important while boards are sawing up or grinding. Application of wax emulsion makes the plate surface smoother and softer which more than twofold increases the operating time of the grinding belt. Wax emulsions have various applications. They can be used e.g. for concrete curing and wood protection as well as on wood panels and textile fibers.

Some advantages of wax emulsion over melted paraffin:

- Small particle size (about 1-5 micron) contributes to better paraffin wax penetration into the wood fiber and provides more efficient hydrophobization.

- Wax emulsions mix well with the melamine- and carbamide-based resins. Wax emulsion acts as a water-repelling agent during the hot pressing of plates. The wax emulsion decomposes and melted paraffin wax hydrophobia the wood pate. Application of special emulsifiers leads to the decomposition of emulsion even before the bending agent becomes hardened which therefore strengthens the waterproof properties of plates.

- It is simple to use because of liquid phase

- No Storage Expenses – The Storage Temperature Of The Wax Emulsion Is 5-30°C, While For The Melted Paraffin Wax Is Over 60°C.

- No Transportation Expenses – In Case Of Using The Wax Emulsion It Isn’t Necessary To Heat The Piping, As No “Freezing” Occurs Inside The Pipes.

- Wax Emulsions Are Not incendiary; Therefore No Fire Risk Or injury Risk Could Be Caused By Its Appliance, While Such Risks Could Occur In Case Of Hot Melted Paraffin Wax.

- Application Of The Wax Emulsion Leads To The 10-20% Reduction Of Resins Without Any Worsening Of The Physio-Chemical Properties Of The Plates.

Wax in Concrete Curing

Most authorities agree that the most feasible and economical means of curing concrete properly is the spray application of a liquid membrane curing compound. These materials are sprayed onto the finished concrete as soon as the final troweling has been completed. A suitable liquid membrane curing compound is capable of maintaining a minimum of 95 percent of the original moisture content in a concrete mix. It is also economical and easy to apply. The liquid membrane method of concrete curing inhibits the loss of mix water by forming a protective membrane of the surface of the slab as soon as it is applied. This membrane is seldom more than 0.002 of an inch thick and it is capable of maintaining a minimum of 95 percent of the mix water present in the concrete mass at the time of application. The curing compound is effective up to 28 days and will then gradually dissipates without leaving a stain or discoloring the concrete surface. There are, primarily, two basic types of non-pigmented liquid membrane concrete curing compound: wax resin and all resin types. The wax resin type is suitable for use on concrete that will not subsequently be painted, tiled or treated in any manner. The wax contained in the material remains on the concrete surface and hampers the adhesion of future paint or mastic. The all resin type is ideally suited for the curing of those areas where there will be a subsequent treatment applied to the concrete, since it leaves no adverse residue on the concrete surface. In fact, the residual film of the all resin type is harder than the wax resin and provides more resistance to abrasion. It also prepares the concrete surface for future treatment and can act as a bond breaker between initial and subsequent concrete pours. Both types are void of pigmentation and are available with a dissipating fugitive dye to aid in easy application.

Specification of RAHA Wax Emulsion:

Packing: Bulk and / or new Iron drum