Polyethylene Wax

Polyethylene Wax description

Polyethylene Wax, also known as PE Wax, is derived from ethylene through a process called polymerization. Manufacturers alter the polymerization process to get a product with desired qualities. However, certain basic properties of the material are common for all Polyethylene Wax.

As a completely saturated ethylene homopolymer, polyethylene wax is linear and crystalline. That is why this material finds applications such as blends, plastic additives and rubber manufacture. Due to its high crystalline nature, this material has unique features such as hardness at high temperatures and low solubility in a wide range of solvents.

The material is thermoplastic, so you can guess how it behaves when exposed to heat. Thermoplastics melt at 110 °C. An interesting feature of these materials is the ability to be heated and cooled without extensive degradation.

Polyethylene wax also features limited poly disparity and molecular weight. Consequently, the material is highly resistant to chemical attacks, has unmatched heat stability and is very flexible in formulating applications.

PE Wax is an ultra-low molecular weight polyethylene consisting of ethylene monomer chains. PE wax has a large variety of uses and applications. PE Wax is available from on-purpose production and as a byproduct of polyethylene production.

This material is available in both HDPE and LDPE forms. As there are many grades and types available, please send us your inquiry by email or WhatsApp so that one of our knowledgeable representatives can assist you in locating the correct grade that matches your requirements.

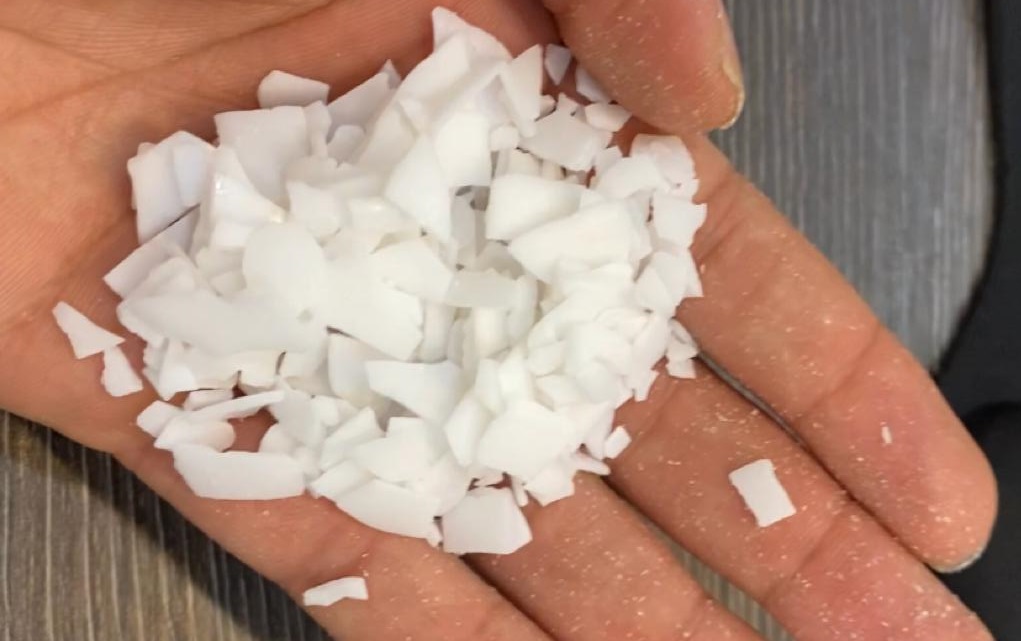

Nevertheless, you can use various methods to identify PE wax from other materials, such as sight, touch, and smell. This wax is similar to plastic sheets. It is a semi-translucent yellow material. It has a gloss surface. If you cut a PE wax, there are neither impurities nor any separation.

The material has lubricant properties, which you can feel by touch. At room temperature, PE wax is brittle and fragile. This is unlike a fake version, which is rough and greasy.

If you want to test the material, consider boiling it in water for five minutes. Real PE wax does not change in shape. If the wax contains paraffin or any other impurity, you will know it through shape change.

Paraffin wax is usually produced as a by-product of oil refining. It has a molecular weight which is usually less than half that of most polyethylene waxes. Because of this and other differences, paraffin wax usually has a much lower melt point and is softer than most polyethylene waxes.

FT waxes are another class of waxes that are only produced by a limited number of suppliers (i.e. Shell and Sasol) due to the large capital requirements involved in constructing these plants. FT waxes are produced in the process of making synfuels. Variations in properties of FT waxes are generally limited to modifying melt point.

Some characteristics of PE wax:

- High softening point

- High melting point

- Excellent thermal stability

- High chemical resistance

- Highly compatible with wax varieties

- Perfect lubrication

- Perfect head resistance

Polyethylene wax application

Polyethylene wax have very unique polymer properties that make them useful in many applications. The major functions of PE wax in many formulations are to either provide lubrication and/or provide physical modification of a formula by changing viscosity and / or melt point.

- Hot melt (increasing the solidification point of adhesives without increasing the viscosity of the mixture, improving the behaviour of hot melts at high temperatures)

- Dispersing loads and pigments (masterbatch)

- Coating paper (improving gloss and flexibility, achieving high-quality finishes)

- Process aids to make mixtures of rubber and PVC, among others, more processable

- Manufacturing inks and toners

- Additives in paraffin mixtures

- Products for filling cables

- Additives for asphalts

- Emulsions

- Textile

- Polishes

- Candles (providing increased hardness and thermal resistance)

Polyethylene wax specification

PE wax is heat-stable, lowly soluble, chemically resistant and hard. Combining these features with abrasion resistance and broad melting points makes the material the undisputable choice for a wide range of industrial applications.

Whether you want to process rubber, manufacture textiles, modifier plastic or coat corrugated board, there is a grade available. As manufacturers may have different grades of the material, please ask so that you can be directed to the one that matches your needs.