paraffin wax production

Paraffin Wax Production

In equilibrium condition Paraffin is completely dissolved in crude oil. Make Changes in temperature and pressure leads to disturb this equilibrium, which might result in paraffin precipitation and crystallization. Basically, the solubility of the paraffin wax is very sensitive to temperature changes. For example, if the temperature of surface of pipe is below the oil Cloud Point (The Cloud Point is the temperature at which paraffin starts to crystallize in the solution), high molecular weight paraffin waxes are deposited.

As a result of having lower (below the Cloud Point) crude oil temperature, paraffin wax crystals precipitate and adhere via colliding with surface and deposits. On the other hand, a mechanism like shear dispersion, Brown diffusion, gravity, thermophoresis, and turbophoresis helps to drive the wax molecule particle to deposit on the pipeline wall. The main factors that affect paraffin wax deposition in flow systems, which are flow rate, temperature deferential, and cooling rate, as well as surface properties.

Wax distillates are produced from three different type namely, the batch-type, continuous-type, and pipe-still processes. They are not obtainable in the cracking process, due to the hydrocarbons of the feed stock are chemically changed, or undergo pyrogenic decomposition, making recovery of paraffinic waxes well-nigh impossible. Naphthenic are preferred to paraffinic feed stocks for the best yields of petrol by the process of cracking.

The combination of wax-oil that distills via petroleum below about 860°F (460°C) including wax would be able to filter from oil in simple filter presses. In fractional crude petroleum, the “raffinate” or cut defined as paraffin distillate, boiling from 170 to 310°C (338 to 590°F) when distilled at a very low pressure, can be separated into solid wax and liquid oil fractions by chilling and filter-pressing.

The solid fraction which are including 65 per cent of wax is the slack wax that is sweated and refined to the normal paraffin wax of commerce. Removing of the wax from pressible wax distillate in order to improve the lubricating properties of the oil and make it chill proof is important. The wax distillate is therefore customarily pumped to the paraffin sheds, where it is allowed to repose in tanks to boost settling at the lowest room temperature. Next it is pumped through a cooling unit bank to hydraulic presses which squeeze out the wax from the chilled distillate.

Next paraffin distillate is obtained from the “crude” a higher boiling cut, and defined as high-viscosity fraction, that is distilled. Moreover, this fraction contains wax, but because of its microcrystalline nature does not lend itself well to separation and filter-pressing. The high-viscosity fraction is cold settled and centrifuged, so yielding an oily wax portion, defined as petrolatum stock and oil. Petrolatum would be refined from the petrolatum stock, or the microcrystalline wax in petrolatum stock that is separated by recrystallization and settling from naphtha solution at reduced temperatures. Sometimes this type of wax is referred to as “petrolatum wax;” at least 85 per cent of its hydrocarbons are of a wax type, whereas petrolatum itself has only 25 per cent of hydrocarbons of a wax type.

Paraffin Wax Analysis

(DSC) defined as Differential scanning calorimetry which is used to detect the physical or chemical changes in a material that are accompanied by absorption (endothermic) or liberation of heat (exothermic). DSC would be able to quantify the thermal events, if the original mass of sample is known. DSC analyses would be able to conducted with 0.1 mg of sample, 5-15 mg is a typical size.

Analytical Technique

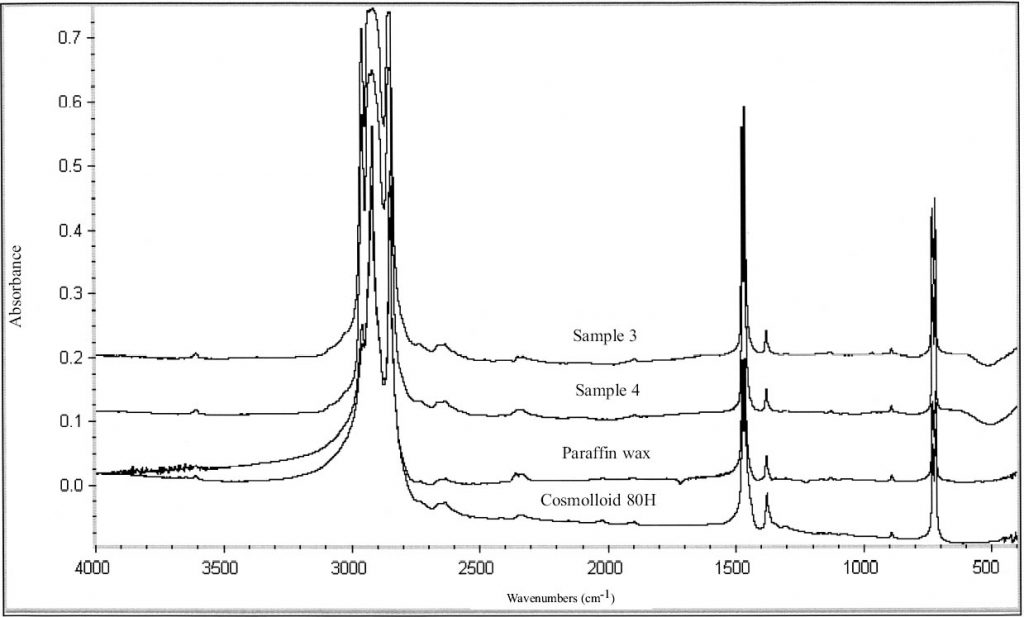

One of the most important analytical techniques available today is (FTIR) which can be defined as Fourier – Transform Infrared Spectroscopy. The most important advantage is that any sample in any state can be studied: gas, liquids, solutions, powders, films and surfaces can be examined by a best sampling technique choice. The other analytical technique is GC that defined as Gas Chromatography.

An example of FTIR diagram analysis

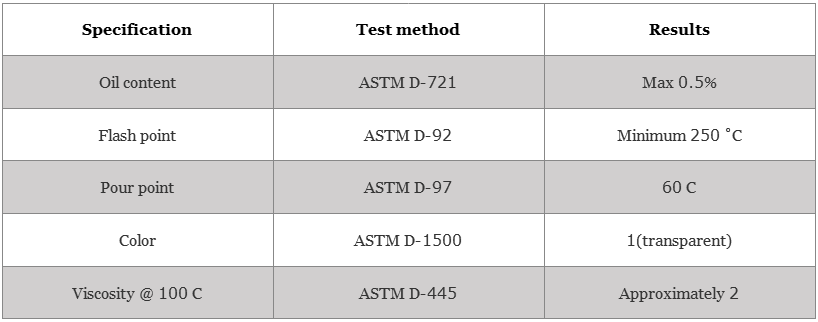

A Kind of Paraffin Wax Analysis

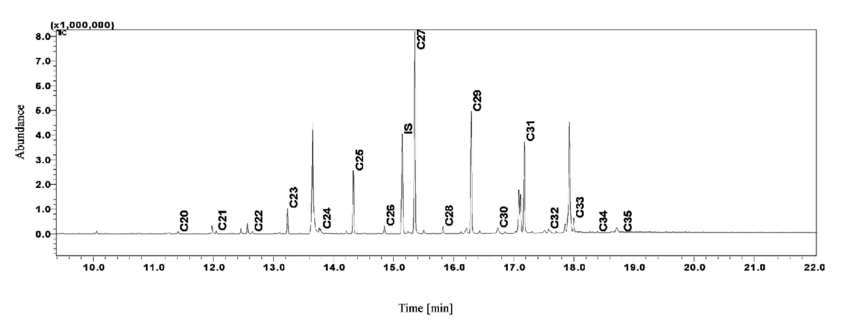

An example of Gas Chromatography (GC)