Emulsion Paraffin

General description of Emulsion Paraffin

A paraffin emulsion is a universal product for adding extra features. It has been successfully used in the woodworking industry as a protective covering. The processed material doesn’t swell and maintains its durability for a long time. Processing exposed chipboard SSP, MDF, and OSB, as they are often used to create home decor. Application Of Wax Emulsion Makes The Plate Surface Smoother And Softer Which More Than Twofold Increases The Operating Time Of The Grinding Belton account of paraffin emulsion covering plates have the following advantages:

- Increased durability;

- The size’s accuracy;

- Smooth surface which subsequently doesn't curve;

- Improved structure formation;

- Deep penetration of fine paraffin particles maximum qualitative protects plate against water;

- Smooth surface;

- More comfortable will be the subsequent coloring material;

In producing of the paraffin wax emulsion, the foregoing emulsifier is admixed with paraffin in a warmed or molten condition.

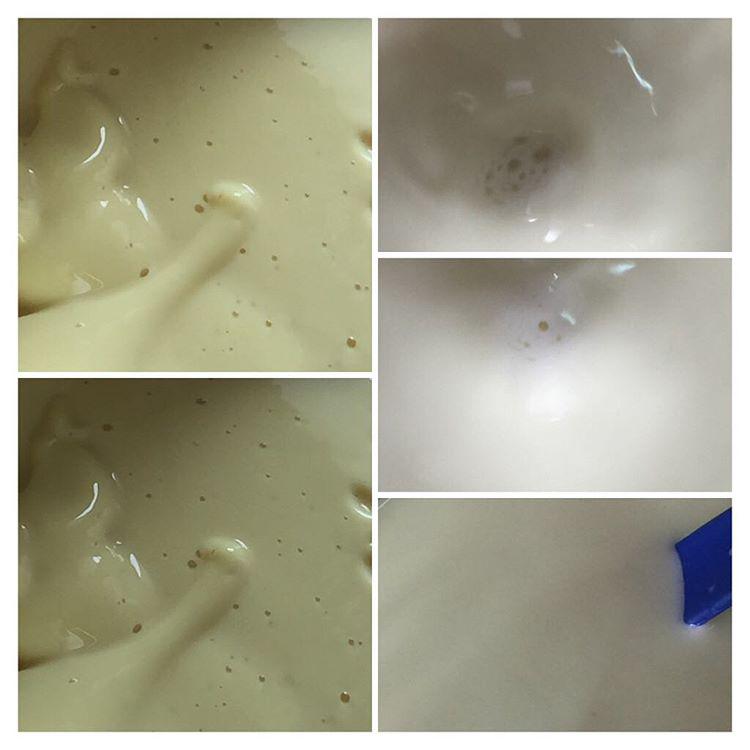

Emulsion paraffin is a mixture of paraffin wax with the desired quantity of water to produce a stable and uniform paraffin emulsion of the desired concentration. The emulsifier-paraffin mass may, on the other hand, be allowed to cool, whereupon a pasty or solid mass results, depending upon the titer of the fatty materials used in producing the emulsifier. The pasty or solid paraffin emulsion will readily disperse upon admixture with water.

The sale of paraffin emulsion from "RAHA Paraffin Company" will allow you not only to avoid dust during sanding or flat working wood sheets. Due to it's a durability and usability of materials increases.

RAHA Paraffin Company guaranty the quality of emulsion paraffin with the arrangement of the international inspector to check quality and quantity of the emulsion paraffin during the loading to the vessel and controlling the production by QC by batch test report before shipping. RAHA Paraffin Co guarantees the quality to meet with ASTM.

Uses of Emulsion Paraffin

Wax Emulsion Is Used In Woodworking Industry To Protect Wood Boards (Particle Board, MDF, OSB) From Water. Wax Emulsion Has Anti-Dust Effect Which Is Important While Boards Are Sawing Up Or Grinding. Wax Emulsion Makes The Plate Surface Smoother And Softer Which More Than Twofold Increases The Operating Time Of The Grinding Belt.

Coatings, ink, coat paper, Bristol board and cardboard, waterproof chipboard, waterproof fibers, ropes and textiles, protect floors, car body, and furniture, coat fruit, and vegetables.

Paraffin Wax Emulsion as Water Repellent for Cotton/Polyester Blended Fabric:

Paraffin wax emulsion is prepared by emulsifying paraffin wax (PW) in water using stearic acid (SA) and triethanolamine (TEA) emulsifying system. A mother emulsion is prepared at different concentrations of PW (10.5—19.1%w/w) and SA (4.5—13%w/w) neutralized to different extents by TEA (25—100% degree of neutralization).

Upon treating 50/50 cotton/polyester fabric with a padding solution containing 50 g/L of different mother emulsions, its water repellency does not exceed the value of 50. Aluminum chloride proves to be the best deactivating agent of the hydrophilicity of the emulsifying agent among other salts including barium chloride, zinc sulfate, and aluminum sulfate. Optimum emulsion ingredients are found to be PW (10.5%w/w), SA (4.5% w/w), TEA (2.4% w/w, to attain full neutralization of SA), and SA/AlCl3 molar ratio (1/1). Treating the fabric with the deactivated emulsion results in enhancing its water repellency rating (up to 80), decreasing its surface roughness, and increasing its stiffness.

A scanning electron micrograph of the treated fabric shows the deposition of the emulsified wax on the fabric surface. Treating the fabric with the emulsion in the presence of a fluorochemical finish, namely Nuva FB of Clariant, proves that the first can be used as an extender for the second. Raising the drying temperature to 160°C gives rise to a water-repellency rating of 100.

Advantage of Emulsion Paraffin

The Sale of the wax emulsion in Donetsk by our company enables to improve the properties of your materials. Due to the properties of the wax emulsion, it can be storage at the temperature of 5 to 30 degrees. Liquid paraffin can maintain its quality at 60 degrees. In winter, there is no need to warm up the emulsion in pipes, since it is not subjected to freezing.

The emulsion contains no flammable components. This significantly increases the safety of the works. It should be noted that a smaller flow of coupling element is provided + (20%). All this allows you to receive the high-quality plate and facilitate their processing.

In Addition, Some Advantages Wax Emulsion Over Melted Paraffin Should Be Noted:

- Small Particle Size (About 1-5 Micron) Contributes To Better Paraffin Wax Penetration Into The Wood Fibre And Provides More Efficient Hydrophobization.

- Wax Emulsions Mix Well With The Melamine- And Carbamide-Based Resins. Wax Emulsion Acts As A Water-Repelling Agent During The Hot Pressing Of Plates. The Wax Emulsion Decomposes And Melted Paraffin Wax Hydrophobicities The Wood Plate. Application Of Special Emulsifiers Leads To The Decomposition Of Emulsion Even Before The Bending Agent Becomes Hardened Which Therefore Strengthens The Waterproof Properties Of Plates.

- Simple Method Of Application Cause Wax Emulsion Is Liquid.

- No Storage Expenses - The Storage Temperature Of The Wax Emulsion Is 5-30°C, While For The Melted Paraffin Wax Is Over 60°C.

- No Transportation Expenses – In Case Of Using The Wax Emulsion, It Isn't Necessary To Heat The Piping, As No "Freezing" Occurs Inside The Pipes.

- Wax Emulsions Are Not Fire-Hazardous; Therefore No Fire Risk Or Trauma Risk Could Be Caused By Its Appliance, While Such Risks Could Occur In Case Of Applying Hot Melted Paraffin Wax.

- Application Of The Wax Emulsion Leads To The 10-20% Reduction Of Resins Without Any Worsening Of The Physico-Chemical Properties Of The Plates.

Packing of Emulsion Paraffin

Emulsion paraffin is packed in new or second hand 180 kg drums, ISO tank, flexi tanks. Each 20-foot container takes 110 drummed emulsion paraffin.

Analysis of Emulsion Paraffin

| Technical properties | Unit | Limit | Test method |

| Congealing point | C | 54-57 | ASTM D-938 |

| Sp @ 25 c | Kg/m3 | 0.93 | ASTM D-4052 |

| Oil content | %m | Max 1.2 | ASTM D-721 |

| Penetration @ 25 c | 0.1 mm | 18-20 | ASTM D-1321 |

| Ph | -------- | 8 | ------- |

| Color | -------- | White | Visual |