Phase Change Materials (PCM)

What is Phase Change Materials (PCM) ?

There are more and more interest in the research of renewable energy sources and materials in the globe with the growing energy crisis. There are different forms in which energy can be stored i.e. mechanical, electrical and thermal energy. Amongst the different energy storage forms, thermal energy storage is the most attractive because of the storing and releasing ability.

Thermal energy can be stored as a change in internal energy of a material as sensible heat or latent heat, or thermo chemical energy storage. Sensible heat storage is carried out by adding energy to the material thus increasing the temperature of the material without changing its phase. Latent heat storage is based upon absorption or release of energy when a storage material undergoes a phase change. Thermochemical energy storage depends on energy absorbed and released by breaking and reforming of molecular bonds in a reversible chemical reaction.

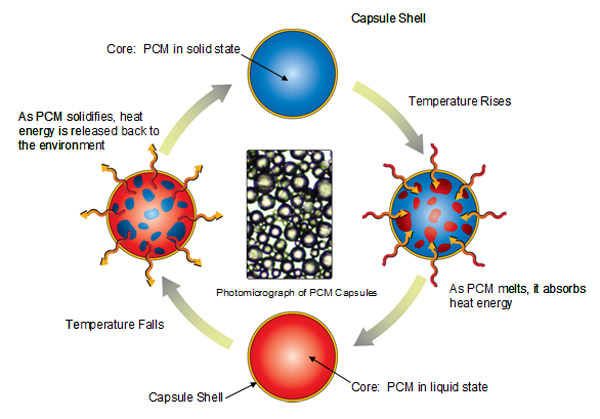

Amongst the above mentioned thermal energy storage methods, latent heat storage is the most attractive due to high energy storage at a constant temperature corresponding to the phase transition temperature of the storage material. The phase change can be solid-liquid, solid-solid, solid-gas or liquid-gas.

In the solid-solid transition, heat is stored when a storage material is transformed from one crystalline state to another. Generally, this system has small latent heat when compared to solid-liquid transitions.

Solid-gas and liquid-gas transitions have high latent heat when compared to solid-liquid transitions, but the major disadvantage is their large volumes which tend to make the system complex and impractical. Solid-liquid transitions are useful because they store a relatively large quantity of heat at a narrow temperature range, with small volume changes.

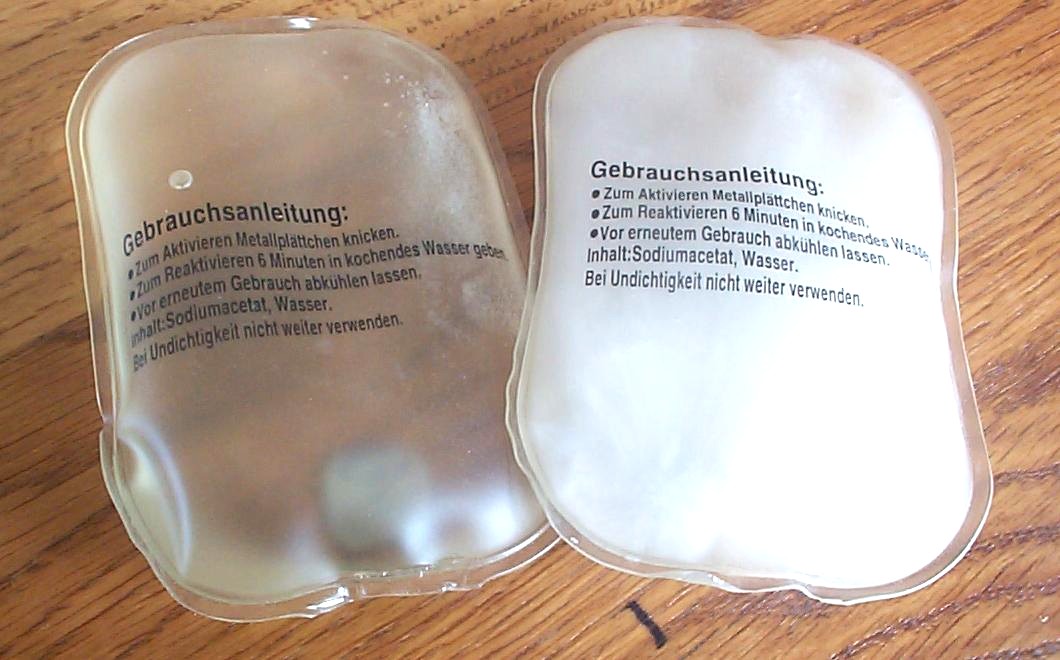

Phase change materials (PCM) are latent heat storage materials. The thermal energy transfer occurs when a material changes from solid to liquid or from liquid to solid and this is called a change in phase or state. However, for PCMs to be used as latent heat storage materials these materials must exhibit certain desirable thermal, physical, kinetic, chemical and economical properties. PCMs absorb and release energy as is shown below

Why Paraffin Wax is a PCM?

Paraffins are high-molecular-mass hydrocarbons with a waxy consistency at room temperature. Paraffins are made up of straight chain hydrocarbons. The melting point of paraffin is directly related to the number of carbon atoms within the material structure with alkanes containing 12-40 C-atoms possessing melting points between 6 and 80 degrees centigrade. These are termed ‘pure paraffins’ and should not be confused with paraffin waxes. Paraffin waxes contain a mixture of hydrocarbon molecules with various carbon numbers with lower melting points and poorer latent heats than pure paraffins. Paraffin waxes are often considered a low-grade PCM.

Paraffin waxes in particular have been of interest due their promising properties as phase change materials (PCM). Paraffin wax is safe, reliable, predictable, less expensive, and non-corrosive. They are chemically inert, show little volume change during melting and have low vapor in the melt.

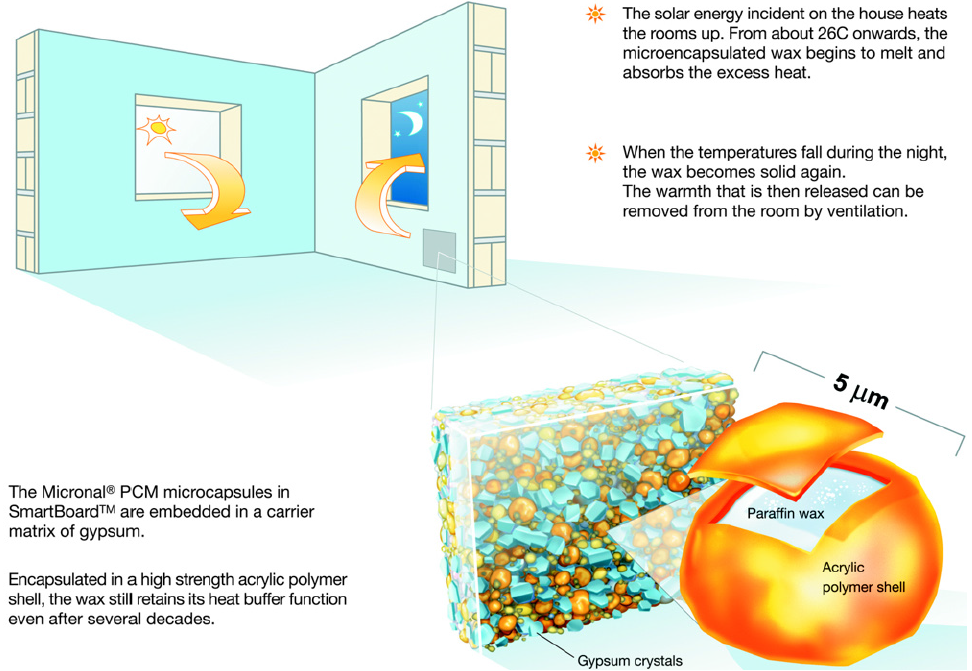

Apart from the favorable properties of paraffin waxes, such as congruent melting and self nucleating properties, they are not easy to be used directly in practical applications because of undesirable properties such as leakage, low thermal conductivity and low thermal stability. However, all of these undesirable effects can be eliminated by modifying the wax and the storage system. There are different ways in which the storage system can be modified, such as direct incorporation of wax into the polymer and encapsulation of wax by microencapsulation or macroencapsulation.

Paraffins form a good PCM candidate for certain applications and certain select temperature ranges. Paraffins have good thermal storage capacity plus the materials are proven to freeze without supercooling. Paraffins also have the advantages of chemical stability over many heating and freezing cycles, high heat of fusion, compatible with most all materials and non-reactive to most materials of encapsulation.

Paraffin wax Applications in Phase Change Materials (PCM)

- electronics thermal management

- infant incubator

- Solar air heater

- Single Slope Solar Water Distiller

- Conditioning of buildings

And etc…

Paraffin encapsulated in beach sand material as a new way to store heat from the sun

Researchers describe a new approach to using paraffin as a PCM. Made from petroleum, paraffin is a waxy material that absorbs heat, melts into a liquid and releases heat as it solidifies. It involves encapsulating paraffin into tiny spheres of silicon dioxide, the stuff of beach sand. The microencapsulated paraffin has several advantages, including a large surface area that can transfer heat, less reactivity with the environment and less likelihood of leaking as it changes phases. They report successful tests of the material for 30 melting-solidifying cycles with no leaks at a temperature of 158 degrees Fahrenheit. The high heat storage capability and good thermal stability of the composite enable it to be a potential material to store thermal energy in practical applications.

Paraffin wax have been widely used for latent heat thermal energy storage system (LHTES) applications due to large latent heat and desirable thermal characteristics such as little or no super cooling, varied phase change temperature, low vapor pressure in the melt, good thermal and chemical stability and self nucleating behavior

Phase Change Material Applications and Uses

• Thermal energy storage

• Solar cooking

• Cold Energy Battery

• Conditioning of buildings, such as ‘ice-storage’

• Cooling of heat and electrical engines

• Cooling: food, beverages, coffee, wine, milk products, green houses

• Medical applications

• Human body cooling under bulky clothing or costumes.

• Waste heat recovery

• Off-peak power utilization: Heating hot water and Cooling

• Heat pump systems

• Passive storage in bioclimatic building/architecture (HDPE, paraffin)

• Smoothing exothermic temperature peaks in chemical reactions

• Solar power plants

• Spacecraft thermal systems

• Thermal comfort in vehicles

• Thermal protection of electronic devices

• Thermal protection of food: transport, hotel trade, ice-cream, etc.

• Textiles used in clothing

• Turbine Inlet Chilling with thermal energy storage

• Telecom shelters in tropical regions

To know every thing about PCMs please click.